Most of us are familiar with the basics of a kitchen fridge, but there’s much more to refrigeration than just keeping food fresh.

Refrigeration is the cooling of a selected area, substance, or object by moving heat elsewhere. In the past, this was done only with snow and ice. Nowadays, temperatures are usually lowered through mechanical refrigeration, which includes a compressor, condenser, expansion device, and evaporator.

The History of Refrigeration

In ancient Rome and Greece, people learned early on that cooling their food preserved it for a longer time. They created snow cellars buried in the ground for this process.

Over time, refrigeration tactics expanded, creating evaporative cooling followed by mechanical refrigeration in the 1700s. About 100 years later, commercial refrigeration entered the scene in the U.S., slowly changing and improving the refrigerants used to keep things cool.

How Refrigeration Works Now

Refrigeration in the 21st century is essential for preserving foods, medicines, and other scientific samples. It is also a crucial part of many air conditioning units.

Most domestic fridges, freezers, and air conditioners use mechanical refrigeration. Both small and large-scale fridges use a closed system to pump a refrigerant through over and over again, removing heat and cooling that area.

Refrigerants are chemical compounds. Since they evaporate at lower temperatures than water, they can extract heat at a faster rate. These refrigerants are condensed into liquid form, slowly evaporating as they’re pumped through the refrigeration system. All the while, they take the heat out and along with them.

You can experience this system in a simplistic form by dipping one of your fingers in cold water, then holding your hand up in the air. You’ll quickly notice how that one finger feels cooler, even as the water evaporates.

Types of Refrigeration

There are four main types of refrigeration: evaporative cooling, absorption, thermoelectric, and mechanical (compression).

- Evaporative cooling pushes hot air over water-soaked areas as it enters a home or building. The water takes in some of the heat and evaporates, leaving the cooler air to enter the home. This is primarily used in HVAC – air conditioning systems.

- Absorption refrigeration, alongside mechanical refrigeration, uses refrigerants; however, this system uses pressure to move heat instead of compressors.

- Thermoelectric refrigeration uses electricity instead of water or refrigerants to cool a space. It combines an electric current and a thermocouple to move heat outside, while the internal side cools down. These are best for smaller areas or to cool things like electronic systems.

- Mechanical refrigeration is the most widely used and incorporates refrigerants in the way we discussed earlier. Since this is the most popular form of modern-day refrigeration, we break down the mechanical components below.

The Main Parts of Mechanical Refrigeration

There are four main parts of a closed mechanical refrigeration system: the compressor, condenser, expansion device, and evaporator. These work together in a loop to remove heat from an area. Then, the heat is moved elsewhere to be expulsed, and it is replaced with cooled air.

Compressor

The first step in a closed mechanical refrigeration system is the compressor. It increases the pressure of the gas in play.

You can find reciprocating, scroll, and rotary compressors. Reciprocating compressors use pistons to reduce pressure and create a vacuum. Scroll compressors are found in residential AC systems and use interleaving scrolls to compress liquids or gases. Rotary compressors, on the other hand, have a variety of designs but usually have one rotor unit combined with a driver. It may or may not have an intercooler as well.

In a mechanical refrigeration system, refrigerants enter the compressor as a low-temperature gas. Within the compressor, the refrigerants transform into a high-pressure, high-temperature gas.

Condenser

The new high-pressure and high-temperature refrigerant gas then enters the condenser. This condenser could be air-cooled or water-cooled.

As its heat is slowly removed, the refrigerant gas condenses into liquid (condensation). The refrigerant is now a high-pressure, low-temperature liquid.

Expansion Device

Expansion devices or valves can come in many shapes and sizes, and they might also be called metering devices. After the refrigerant leaves the condenser, it needs to experience a pressure drop. This is where the expansion device comes in.

The drop in pressure makes the refrigerant boil in a process called “flashing.” This creates a 2-part mixture.

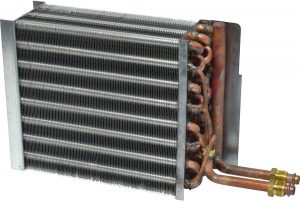

Evaporator

The evaporator is another heat exchanger, just like the condenser. It is usually in the shape of a tube or coil. The refrigerant is then pushed across the evaporator, where its heat is absorbed and you’re left with cooler air.

The refrigerant is then cycled back into the compressor, where the process can repeat in a loop to push in more cool air.

Maintaining a Refrigeration System

Refrigeration systems are often running 24/7 or for a large part of the day, meaning they will need some upkeep to keep things in order. You can maintain refrigeration systems yourself or hire a professional to help.

Not all of these maintenance tips will work for each refrigeration system – you will be doing different things to your fridge than you would to a window AC unit. Always look up the best practice for your machine before trying to fix or upkeep anything yourself.

Compressor Maintenance

Compressors should have the following maintenance every 6 months:

- Tighten electrical connections

- Check electrical components (frayed wired, corroded terminals, etc.)

- Check control system (oil safety, high-pressure controls, etc.)

- Check oil level

- Check defrost controls

- Check refrigerant line insulation and levels

- Check capillary and super hose lines

Condenser Maintenance

Every six months or sooner, you should do the following on your condenser:

- Clean and wash the condenser coil

- Check condenser fans

- Tighten all fan screws

- Replace worn motors, if applicable

Evaporator Maintenance

The evaporator of your refrigeration system should be inspected every month to make sure it defrosts properly. Too much ice on the coil could negatively affect your refrigeration system.

Additionally, every six months you should:

- Tighten all connections found in the electrical panel

- Inspect the fan motors and blades

- Inspect the defrost heaters

- Clean the drain pan

- Clean the coil surface

Filter Maintenance

Plenty of refrigeration units – especially window AC units – have filters that need to be cleaned out regularly. With all of the air moving in and out, it’s only natural that dust and dirt will also make their way through.

These filters may be washable or completely replaceable. Window units should be cleaned monthly when running daily. Refrigeration systems with water or ice-makers should also have their filters replaced regularly.

Professional Maintenance

When in doubt, always consult with a professional. Heating, ventilation, and air conditioning (HVAC) technicians usually work with cooling systems, including air conditioning units and refrigeration (HVAC-R). They can perform routine maintenance, resolve issues, or install new refrigeration systems quickly and professionally.